Sourcing Packaging Solutions for the Food and Beverage Sector in 2025

As 2024 comes to an end, the food and beverage sector is gearing up for the changes of 2025, particularly in packaging procurement, which is set for considerable transformation. Continue reading for an in-depth exploration of the factors influencing the industry, important upcoming milestones, and the necessary adjustments in procurement strategies.

All You Need for Personalized Glass Bottles!

A bespoke glass bottle is uniquely tied to a particular brand. The creation of custom glass bottles serves as a strategic marketing initiative aimed at fostering lasting connections with consumers. By designing personalized glass bottles with distinctive shapes and branded features, companies aim to stand out. Many brand owners opt for custom glass designs to enhance brand loyalty and reinforce their uniqueness and visibility in the market.

Choosing the Best Jar Lids for Canning: A Guide

Preserving your own food is a classic tradition that allows you to savor homemade delights throughout the year. Whether you're preparing jars of jam or storing robust stews, selecting the appropriate lid and jar is crucial.

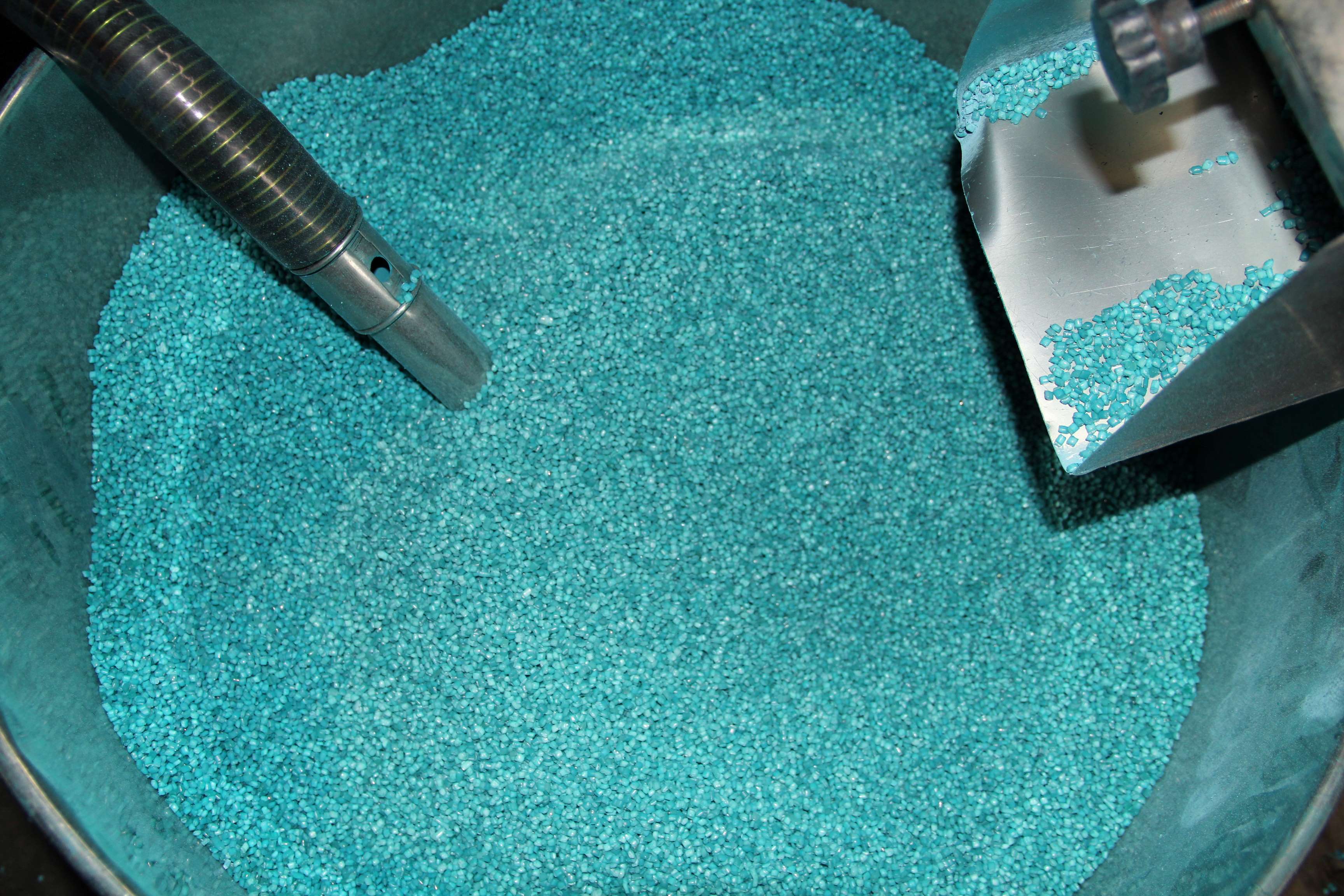

What are Plastic Pellets?

It's important to highlight that pellets play a crucial role in many manufacturing processes, as the plastics sector is vital to the global economy. Now, let's delve into everything you need to know about plastic pellets.

Refreshing the Future: The 7 Most Innovative Breakthroughs in Beverage Packaging

Recently, there has been a notable shift towards sustainable and environmentally friendly packaging options, mirroring the increasing consumer interest in eco-conscious products. Let's delve into some of the pioneering packaging innovations within the beverage industry that are establishing new benchmarks.

5 Essential Approaches for Achieving Success in Food Branding: The Definitive Guide to Glass Packaging

Glass packaging has surfaced as a preferred option for brands looking to enhance their reputation, attract environmentally aware consumers, and guarantee the safety of their products. This guide will delve into five essential strategies that can empower food brands to achieve success by leveraging glass packaging.

More Than Just a Bottle: 7 Creative Ideas for Enhancing Glass Bottle Decor

Whether you're dealing with drinks, beauty products, or gourmet items, decorative techniques for glass bottles can transform your offering from average to exceptional. Let's delve into seven impressive decoration strategies that will enhance your brand's attractiveness and increase sales.

Approaches to Improve Cooling Efficiency in PET Preform Molding to Reduce Cycle Times

When manufacturing bottles from PET resin, it's essential not only to use top-grade PET resin but also to enhance the efficiency of preform injection molding. To significantly cut down cycle times, molders can implement several strategies, with efficient cooling playing a crucial role in the preform injection molding procedure.

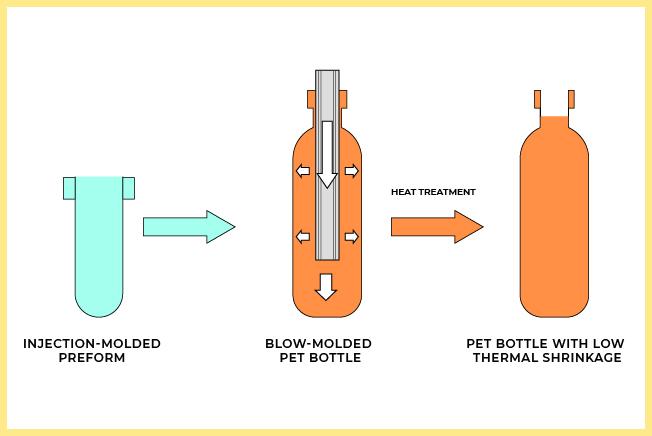

How a PET bottle is manufactured

Among the various plastics available, manufacturers typically opt for Polyethylene terephthalate (PET) when it comes to creating bottles for food or drinking water. This material is favored due to its ability to produce lightweight, robust, and long-lasting bottles. While the production process may differ slightly among manufacturers due to their unique techniques, the fundamental method for bottle manufacturing remains consistent across the industry.